High Performance Components Designed for Reliability, Safety & Efficiency

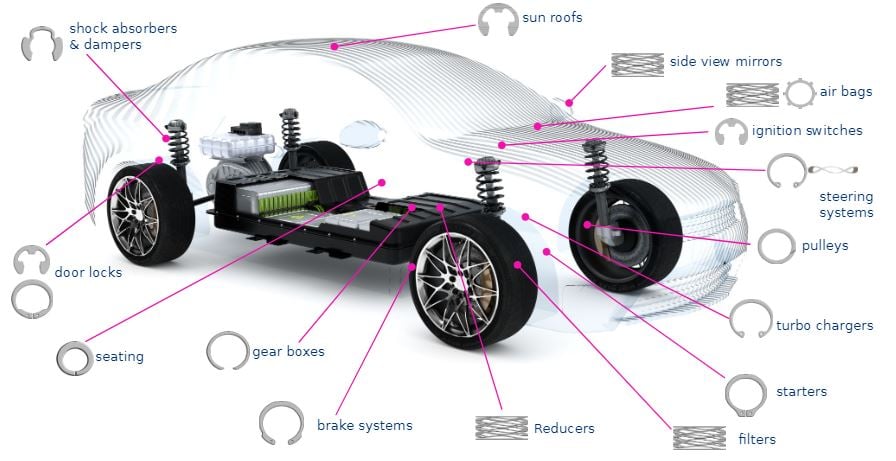

For more than 60 years, Rotor Clip has supported the automotive industry with the highest quality circlips to ensure the reliability and safety of automotive designs and applications. As the industry rapidly evolves and cars become fully electrified, lighter, and more efficient; Rotor Clip is proud to be part of this innovation by engineering and manufacturing parts for electric car manufacturers worldwide.

Rotor Clip circlips, spiral rings, wave springs and self-compensating hose clamps are made from high-quality, high-strength materials and finishes, including stainless steel and several other specialty materials so they will withstand the harshest conditions including extreme temperatures and moisture. Parts that go into safety-critical applications must meet the highest standards for quality, reliability, and cleanliness.

A single car produced today can have over 100 applications for our product. From mirrors to brakes, door locks to filters - our reliable, high-quality parts support leading automotive companies worldwide, highlighted in this electric motor using a balanced spiral ring with a self-locking feature.

Because of the high RPM of the EV bearing, the self-locking ring is used to resist expansion due to centrifugal force and keep it seated in its groove. These self-locking rings work by having a small tab that “locks” into an opposing slot. Without the self-locking feature, the ring could potentially grow in diameter whilst spinning, to the point that it would slip out of the groove, leading to a failure.

The same spiral ring can also be statically balanced to reduce the vibration in the motor. Maximum static imbalance requirements dictated by the customer are achieved by removing material with cut-out slots positioned opposite the ring’s gap. These slots centralize the ring’s center of gravity by compensating for the material missing at the gap.

Having a self-locking feature and balanced slots in the same spiral ring is not mutually exclusive. Some applications may just require a self-locking ring to keep the ring in the groove but not need it to be balanced. Whilst other applications may need the ring to be balanced but not require self-locking. This condition is often found where housing rings are used in high-speed rotation applications. The ring may need to be balanced to reduce the vibration in the application, but the housing constrains the ring from growing outward due to centrifugal force.

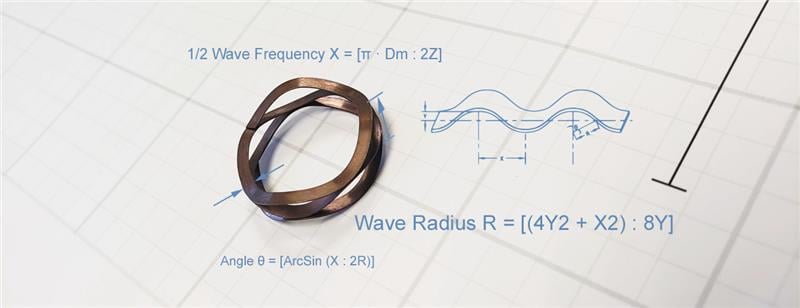

Spiral wound rings are ideal solutions to applications that need a custom solution as they can easily be changed to suit many needs: ring diameter, thickness, radial width, material type, removal provisions, tamper proof features, balance slots, self-locking features and much more are examples of features that be customized.

In the same vehicle, other applications include things such as a bearing preload which may be using a wave spring. Our wave springs can save up to 50% in axial space compared to conventional spring elements. They offer low spring rate & linear load-deflection-curve. When considering a spring for which is critical at the lowest axial working heights in such an application, wave springs do not negatively influence the efficiency and cruising range of EVs. This is due to a reduction of friction within the bearing when comparing them against conventional spring elements.

As automotive design engineers work to innovate and streamline their industry, our own team of dedicated engineers work with them to develop the most cost-effective and functional components for these unique applications. From prototype through to production Rotor Clip engineers work closely with potential customers to discuss the best solution to any application that could involve one of our products.

For assistance with your application, contact us at info@rotorclip.com or visit www.rotorclip.com