Top 10 things an engineer looks for in a retaining ring supplier.

Here are ten things that an engineer might consider when evaluating a retaining ring source:

.png)

Here are ten things that an engineer might consider when evaluating a retaining ring source:

.png)

Traditional coil springs are widely used throughout a variety of applications across nearly every industry. The typical end configuration for coil springs is where you have a helix, and the last turn is bent down, touching the second to last turn and ground to form a shim.

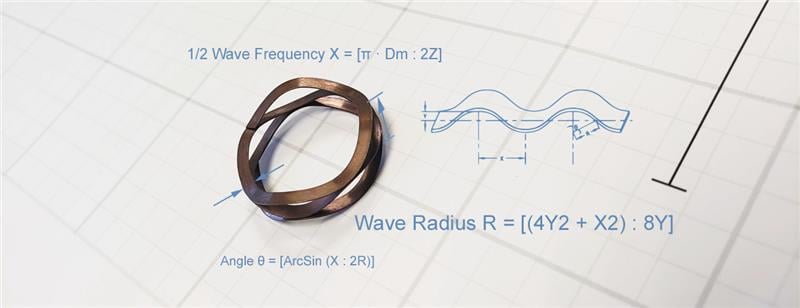

Rotor Clip manufactures the largest range of wave springs in the market, with the ability to manufacture springs from 3 mm to 635 mm. Wave springs offer space savings in an axial direction, in which 50% of the operating height can be reduced. Wave springs produce loads in shorter spaces by distributing the loads over the waves themselves from bending, opposed to torsion. When specifying wave springs, there are many features that can be modified to suit individual application requirements. Whether you need a custom or if a standard configuration works, when it comes to coiling, modifications and customizations are often simple, as it’s just an adjustment and no special tooling is needed.

With multi-turn wave springs, customers often think they need a shim ended part based on conventional coil spring designs. However, Rotor Clip engineers can help assess the right end-type for wave springs based on your application requirements. Here are the following end-type configurations offered for both single-turn and multi-turn wave springs:

When your design calls for a spring, traditional coil or disc springs probably come to mind. But in many cases, the routine choice may not be your best choice. After all, requirements like force handling, work heights, travel distances and avoiding wear and tear must be met, all in a small amount of space. Rotor Clip produces a full line of multi-turn and single-turn wave springs that are made from coiled flat wire with waves added to give them a spring effect. In certain applications, they offer distinct advantages over traditional springs, such as saving space by up to 50 percent in the axial direction.

What are the main factors to consider when selecting a grade of stainless steel?

-1.png)

Retaining rings—also known as snap rings and circlips—are metal fasteners installed into a groove on a shaft or in a housing or bore to retain an assembly. They keep parts in place using a compact, lightweight design that requires fewer machining operations than other fastening techniques.

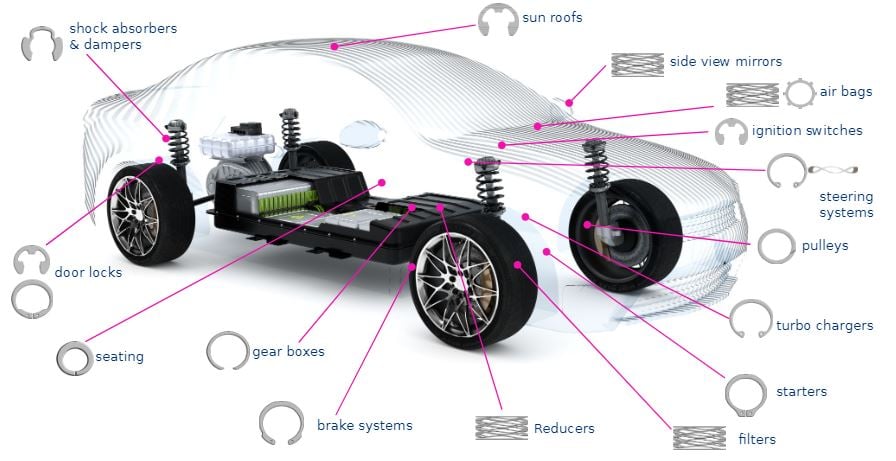

For more than 60 years, Rotor Clip has supported the automotive industry with the highest quality circlips to ensure the reliability and safety of automotive designs and applications. As the industry rapidly evolves and cars become fully electrified, lighter, and more efficient; Rotor Clip is proud to be part of this innovation by engineering and manufacturing parts for electric car manufacturers worldwide.

-1.png)

In the early 1960s, the Volkswagen Beetle was introduced to the U.S. market. The German automotive company was tasked with marketing a small, compact vehicle, and against all odds rose to popularity through the famous “Think small” campaign. Fast forward to the current state of the automotive industry today, with exponential growth and development in the electric and autonomous vehicle markets, design engineers across a variety of industries are now tasked with thinking small, but in terms of the components used.